Complete OEM O2 Measurement Solution for Combustion Control

The Zirconia Oxygen Sensor System offers a complete solution, removing the need for customers to develop their own electronics. Frequently used in combustion control systems, burning coal, oil, gas and biomass.

The Zirconia Oxygen Sensor System – Combustion consists of SST’s fast response (<4s T90) zirconium dioxxide (ZrO₂) screw fit sensor in conjunction with the OXY-LC oxygen sensor interface board.

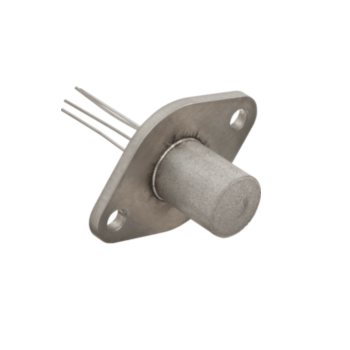

The system employs a well proven, zirconium dioxide element at its heart and, due to its innovative design, does not require a reference gas. This, along with its rugged stainless steel construction means the sensor can be used in extreme temperatures and aggressive environments.

These oxygen sensors use a unique closed loop measurement system. While the sensor continuously measures the oxygen level, a heartbeat signal is also generated, providing an immediate warning of any failures.

The sensor is housed in a short probe with an M18x1.5mm thread, making installation quick and easy. The oxygen sensor can operate in temperatures ranging from -100°C to 250°C and has a lifetime of up to 10 years (depending on the application).

When connected to the OXY-LC interface board, the zirconia oxygen sensor can measure oxygen concentrations of 0.1% to 25% and 0.1% to 100%.

Key features

- Industrial grade oxygen sensor and sensor control electronics

- 0.1…100% O2 (2mbar to 3bar ppO2) measurement range (with electronics interface)

- Linear across its range

- No reference gas requirement

- Operating temperature range -100…+250°C (-148°F…+482°F)

- Response time <4 secs

- Supply voltage 8-28VDC

- Stainless steel sensor with M18x1.5 process connection

- Output options 4…20mA, 0…10VDC or RS485

- 1.2m, 5-core cable